Convert it to gallons by dividing by 231. DAY TANKS Design Considerations of a Day Tank Fuel Transfer System p.

Hydraulic Tank Design For Rotational Moulding Plastic Molding

Reservoirs have a greater diameter than height and can be used with a pumping.

. The advantage of using simulation techniques in the field of hydraulic tank design will be explained by illustrating the results of on-going research tasks. 3 A detailed geotechnical investigation should be made during the design phase to ensure that the tank foundation will be stable and protected from excessive settlement. Design considerations of hydraulic structures.

There are thousands of hydraulic structures within the river and canal networks of the UK. An overall hydraulic performance curve for the designed culvert indicates headwater and outlet velocity characteristics for the entire range of discharges. On the one hand as far as possible to meet the requirements of heat dissipation on the other hand when the hydraulic system stops working it should be able to accommodate all the working medium in the system.

HYDRAULIC CIRCUIT DESIGN AND ANALYSIS A Hydraulic circuit is a group of components such as pumps actuators and control valves so arranged that they will perform a useful task. Tools Cleaning Safety Industrial Office Supp More. In this chapter the word tanks will be used to describe treated water-storage facilities although the term reservoirs is preferred by some whereas others use the word reservoir to describe only ground-level and buried tanks The key considerations in the hydraulic design of water storage tanks are described in the following sections.

Never undersize the reservoir. HYDRAULIC DESIGN OF DESILTERS 34 31. For cylindrical reservoirs we use the same formula that we used to determine the fill volume of a hydraulic cylinder 314 x r² x L 231 equals gallons.

Water Level Control 46 46. 1 the tank must have a large enough volume. Hydraulic tank design considerations Written By mikewhan85358 Tuesday March 29 2022 Add Comment Edit.

Over sizing the reservoir by 5 to 15 gallons will offer substantial benefits by allowing the. L is length of pipe feet D is diameter of pipe square feet V is mean velocity fps C h is Hazen-Williams friction coefficient. The elevation of the water is accomplished by storing the required water on top of water.

Concrete tanks should not be located in areas where there will be vegetation or trees on top of or next to the tank which may cause root damage to the tank. For square or rectangular tanks multiply the length in inches by the height by the width. Of course cooling capacity depends upon the differential between hydraulic fluid temperature and.

In accordance with ISO 14121-1 a risk assessment must be conducted to ensure there are not any predictable risks in the design that could carry over into the field. N Energy dissipated due to friction and turbulence during pump operation Major Losses Friction Losses Due to friction between pumped water and inner surface of piping H f 302 L D-1167 VC h185 Hazen-Williams Formula where. At an absolute minimum the additional analysis of the 1 AEP discharge is required for both the existing and the proposed conditions.

The challenges of mobile reservoir design. Register for Free Shipping. Reasonably foreseeable misuse shall not cause hazards.

Hydraulic Design 37 4. Hydraulic power packs come in many different shapes and sizes. Design requirements for RCC mixtures including RCC properties and mixture proportioning procedures Chapter 5.

Design considerations for RCC buttresses for concrete dam modifications. More retention time is likely needed for systems with grinder pumps or with large amounts of. When designing the optimum hydraulic reservoir most of the considerations are in keeping the oil clean and cool.

Hydraulic system designs for heavy equipment and other machinery must take into account how and where the system is to be used. Hydraulic system design considerations. Free Shipping on Qualified Orders.

Request a Quote Today. October 20 2014 By Josh Cosford. From very large and generally stationary industrial units through too much smaller and compact packs designed for mobile applications.

Hydraulic oil spends most of its time in the reservoir and as such various tank design criteria provide benefits for the hydraulic system as a whole. The drain D was dead center in the V- bottom. Materials Science and Engineering PAPER OPEN ACCESS Design of an optimal hydraulic tank configuration To cite this article.

This way the aerated oil stayed toward the top any particles that bypassed the filter stayed on the inlet side. Ad Buy hydraulic tank at Amazon. Flushing Gate 46 45.

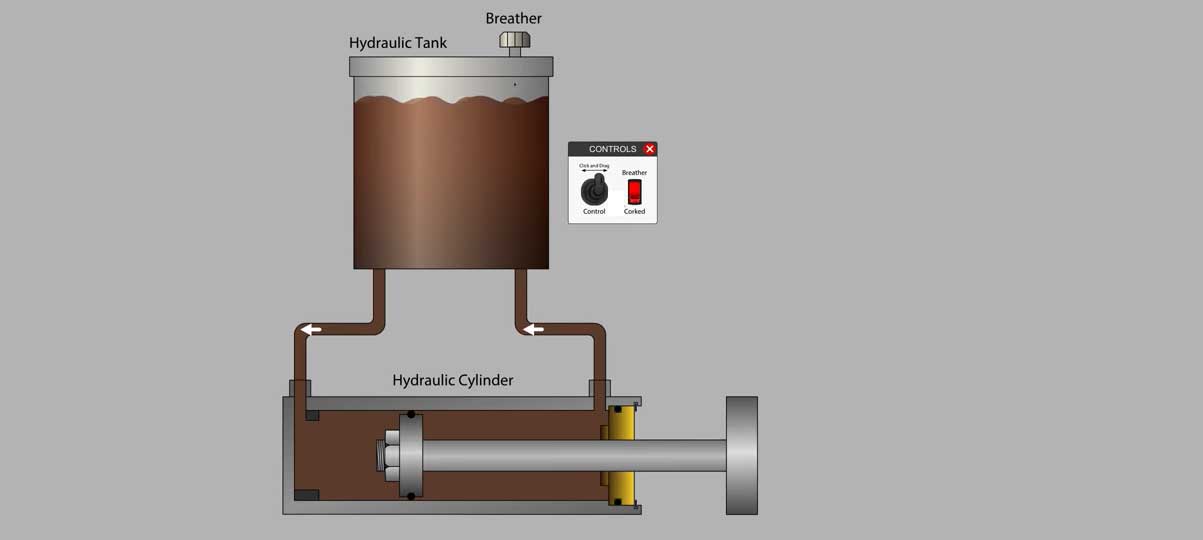

The reservoir often just called the tank also provides significant surface area for cooling of the hydraulic fluid. Ad Custom Engineered Solutions for Your Bolting Tensioning Needs. FUNCTIONS OF A HYDRAULIC TANK A hydraulic tank is an important part of a hydraulic power unit and represents the heart of the hydraulic system.

The tank height is greater than the tank diameter. Millions of Products Top Brands. You can imagine a 50-gallon steel box with 150 F liquid inside will radiate a fair amount of heat even if airflow was minimal.

In addition some systems that have proportional or servo valves may also be highly sensitive especially to fluid contaminants. 2 PUMP PRIME Maintaining the prime on a pump is critical. Construction methods from batching through final testing Chapter 6.

The most susceptible components in any hydraulic system are the pump motors and cylinders. Hydraulic System Design Operation. Design Considerations 35 33.

Load W 06 ton60kN OPERATING PRESSURE p 25 M Pa Lift range L 20. Hydraulic Powerpack Design Considerations Hydraulic power packs are the very heart of your hydraulic circuit so they need to be designed correctly. Escape Weir 46 44.

Richard Chubb Associate Director and Delivery Manager for our Collaborative Delivery Framework with the Environment Agency examines some of the key design considerations when delivering new or reviving. Fuel must be maintained in the suction side pipe with no air pockets. The excess reserve oil in a hydraulic system is to dissipate heat and prolong the life of the pump.

Design Criteria Tank 45 43. The baffle ran the length of the v-bottom tank slightly offset from the center. We Offer an Extensive Line of Hydraulic Tensioning Equipment to Meet Your Exact Needs.

Below are common tanks with design considerations related to managing commercial flows. Septic tanks for commercial systems are recommended to have at least three days of design hydraulic retention time with four-plus days for challenging streams. This will yield the volume in cubic inches.

The following points should be considered when designing the fuel tank. Foot valves at the main tank or check valves at the Day Tank can be used to prevent fuel flowing back to the main tank and losing prime. At the end opposite the return there were 2 15 dia holes Hlocated about 3 and 6 from the bottom.

The most common configuration used for water storage is the reservoir. Here are some important points to consider in designing and using hydraulic systems. Standpipe height usually does not exceed 140 ft.

Ad An Endless Assortment on One Easy-to-Use Site. HYDRAULIC DESIGN OF FOREBAY TANK 45 41. Design considerations for new RCC gravity dams Chapter 7.

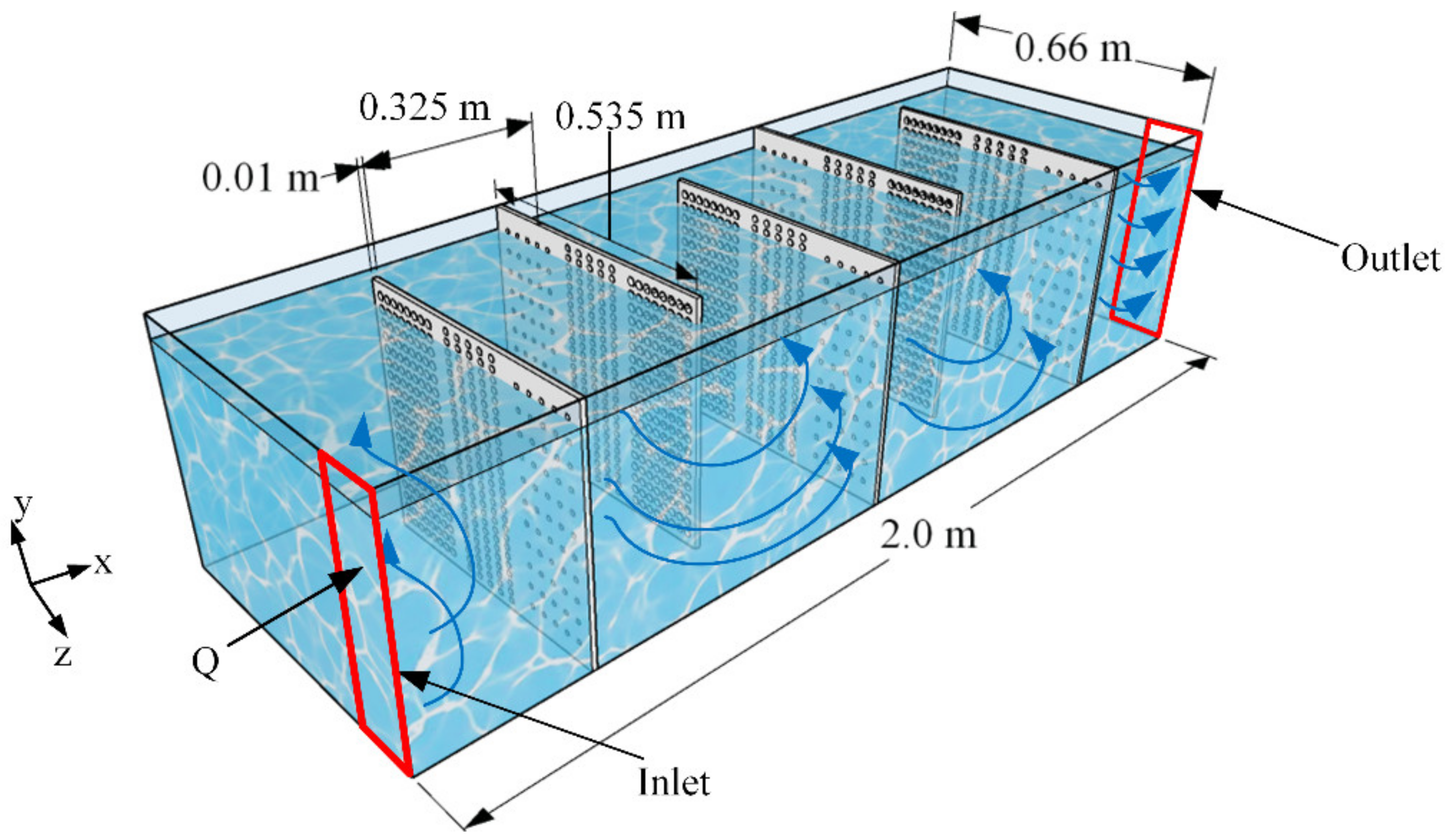

Water Free Full Text A Perforated Baffle Design To Improve Mixing In Contact Tanks Html

Are You Using The Right Tank Design For Your Industrial Mixing Application Part 3 Proquip Inc Mixing Solutions

Troubleshooting Hydraulic Reservoirs Breathers And Filters

Hydraulic Reservoir Design Considerations

Parts Of A Toilet And How It Works 3 Full Diagrams Homenish Toilet Handle Sewage System Toilet Tank

0 comments

Post a Comment